Yes, we offer DFM support to optimize designs for machining efficiency without compromising functionality.

Empower next-gen robotics with MYT’s reliable, high-precision components. Let’s bring your designs to life—request a free quote today

From high-precision gears and actuators to custom tooling and enclosures, we create performance-driven components that enhance robotic system efficiency and reliability. Our advanced machining capabilities ensure tight tolerances and superior quality, supporting everything from industrial robots to autonomous machines. With expertise in a wide range of materials, we provide robust solutions that meet the demanding standards of robotics engineering.

At MYT Machining, we provide precision CNC machining solutions tailored to the robotics industry, where accuracy, durability, and innovation are key. We specialize in transforming complex designs into high-performance components for robotic systems, ranging from industrial robots to advanced automation solutions.

Our capabilities support the full spectrum of robotics applications, from one-off prototypes to large-scale production runs. With a focus on tight-tolerance machining and quality control, we work with materials such as aluminum, steel, and engineered plastics to deliver custom parts that meet the highest standards of performance and reliability.

Whether you’re building robotic arms, mobile robots, or automation tools, our custom CNC solutions ensure your robotics systems operate with precision, efficiency, and longevity.

We offer precision-machined components designed to enhance the performance, reliability, and functionality of robotic systems in various applications.

Equipped with the latest technology and advanced machinery to ensure precise, high-quality manufacturing.

High-accuracy CNC manufacturing with advanced technology and unmatched efficiency.

Streamlined CNC production using state-of-the-art machinery for consistent quality.

Expert fabrication and assembly of intricate CNC components under one roof.

Fully automated CNC operations delivering fast, precise, and reliable machining.

Optimized for delivering premium-quality CNC parts with speed and precision.

End-to-end CNC manufacturing with seamless workflows and superior results.

We offer a variety of metal alloys and high-performance plastics for robotics parts, ensuring durability and reliability.

Our surface finishes, including anodizing and electroplating, improve corrosion resistance and performance in robotic applications.

MYT delivers precision CNC machining services to a wide range of industries including aerospace, automotive, electronics, medical, and others. Here are the industries we serve, with reliable, high-quality parts tailored to meet each sector’s specific engineering demands.

Discover why clients trust MYT for CNC machining. Our testimonials reflect satisfaction with our precision, quality, timely delivery, and dedicated support—building long-term partnerships across industries worldwide.

Hear from industry leaders who rely on MYT Machining for high-precision CNC solutions that drive their success

MYT’s CNC milling delivered unmatched accuracy that elevated our production quality beyond expectations.

Deep hole drilling precision from MYT allowed us to meet strict aerospace standards seamlessly.

MYT delivered high quality, precise CNC parts with tight tolerances and quick turnaround times, ensuring seamless project execution

MYT’s expertise in CNC machining ensured durable, perfectly machined components for our project, meeting all performance requirements

MYT specializes in high-precision CNC machining, turning your concepts into functional, high-quality parts with speed and accuracy. Equipped with advanced technology and skilled craftsmanship, we deliver production-ready components that meet your exact specifications, regardless of complexity.

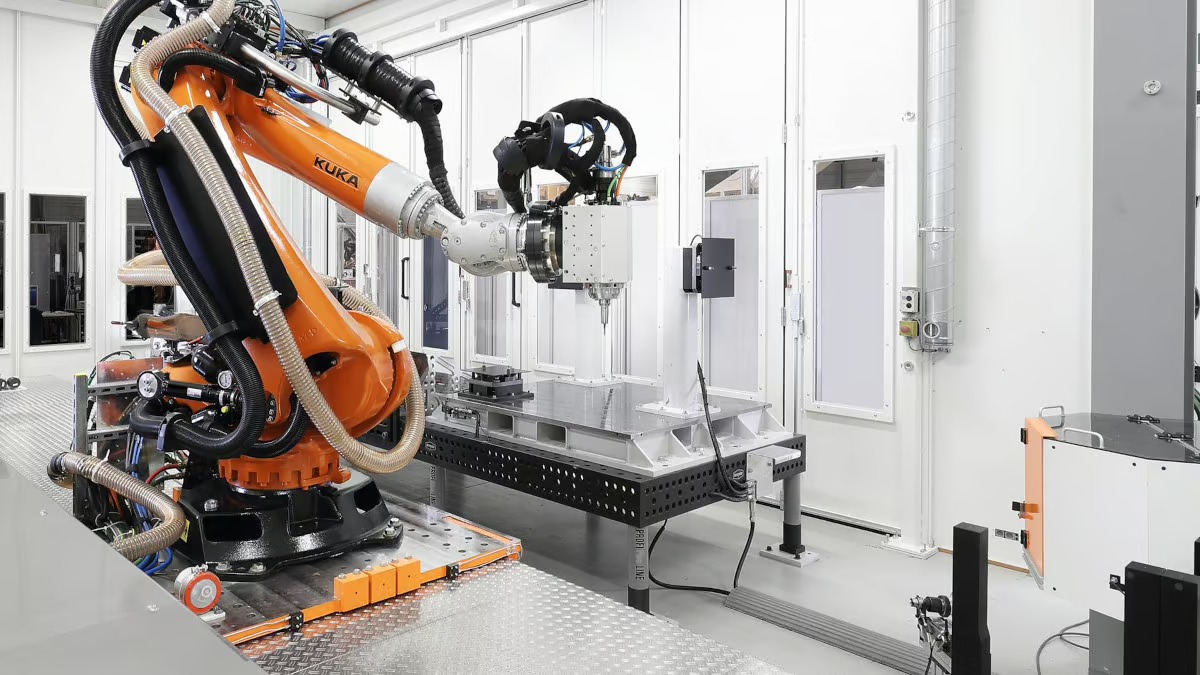

As the demand for robotic automation surges across global industries, precision and adaptability have never been more critical. At MYT Machining, we specialize in CNC machining for robotics automation, delivering reliable, scalable, and high-precision solutions tailored to the fast-evolving world of industrial robotics.

From custom parts to complete assemblies, we support manufacturers, integrators, and automation engineers with the components and expertise they need for modern CNC machine automation.

The precision required in robotic CNC systems demands exacting tolerances and material consistency, traits that only advanced CNC machining can reliably produce.

Both CNC robotic arms, robotic milling machines, and custom end-effectors can perform at their best with our precision-machined parts.

We offer an end-to-end service for your robotic automation projects, from concept to production, including:

We construct detailed parts that go into:

Our advanced CNC machine automation integration ensures seamless compatibility with your existing automation systems.

Our expertise in robotic CNC solutions spans a variety of sectors:

Auto Industry: Robotic welding and assembly require precision parts.

Aerospace: For aerospace, making lightweight pieces for robotic inspection systems

Medical: Robots used in medicine need parts that are very accurate.

Electronics: Equipment with parts made using Computer Numerical Control machining

General Manufacturing: Tooling, frame construction, and fixture work

We supply both items and advice to clients who use or include these technologies:

Undoubtedly, we’re the best CNC automation solutions providers in the market. Partner with us to build reliable, future-ready CNC automation systems with the highest level of performance.

With decades of experience in automation in manufacturing, we bring unmatched value and reliability to our clients. Here, I will list the reasons why top robotics integrators count on MYT Machining.

Let’s help you bring your robotic CNC machining project to life with parts that exceed expectations. We’re more than an automation solutions provider, we’re your innovation partner.

Contact MYT Machining now and discuss your CNC machining needs for automation in robotics. If you are at a prototype stage or starting on a big production project, we are equipped to help. Give us a call or request a quote.

Explore MYT’s blog for expert insights on CNC machining, industry trends, manufacturing tips, and technology updates—designed to keep you informed, inspired, and ahead in precision engineering.

Can you assist with design improvements for manufacturability?

Yes, we offer DFM support to optimize designs for machining efficiency without compromising functionality.

What’s your lead time for a new robotic prototype part?

Typical lead time is 5–7 business days for prototype parts, depending on complexity and finish.

Can you help us iterate designs quickly during development?

Absolutely—we specialize in rapid prototyping and low-volume runs for robotics R&D teams.

Do you work with lightweight materials for drones or mobile robots?

Yes, we machine aluminum, titanium, and carbon fiber to help reduce weight while maintaining structural integrity.

What tolerances can you achieve for robotic parts?

We routinely hold tolerances down to ±0.01 mm, and tighter where needed depending on geometry and material.